|

Rare-Earth

Metals

H2 |

Introduction

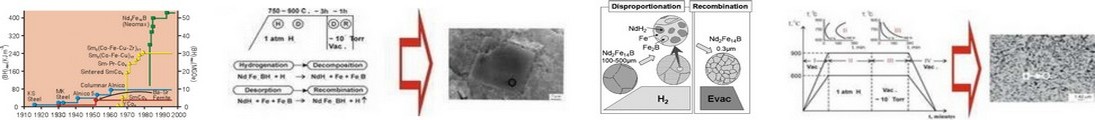

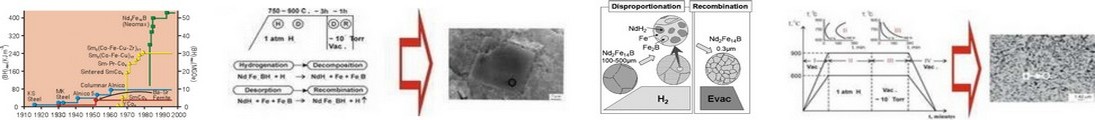

Currently, permanent magnets made from Nd2Fe14B type

alloys possess the best magnetic properties with maximum magnetic energies (BH)max

reaching up to 50 MGOe (400 kJ/m3) and extremal values of coercive

force and remanence [1]. Permanent magnets made from these alloys are widely

used in many civilian applications including electronics, automotive industry,

radio engineering and automation. e.g. for the small motors in CD and DVD-ROM

drives, zoom lenses, camcorders etc. Improvement of the properties of the

magnets will permit miniaturization of the user end products and therefore

constitutes a significant advance in engineering.

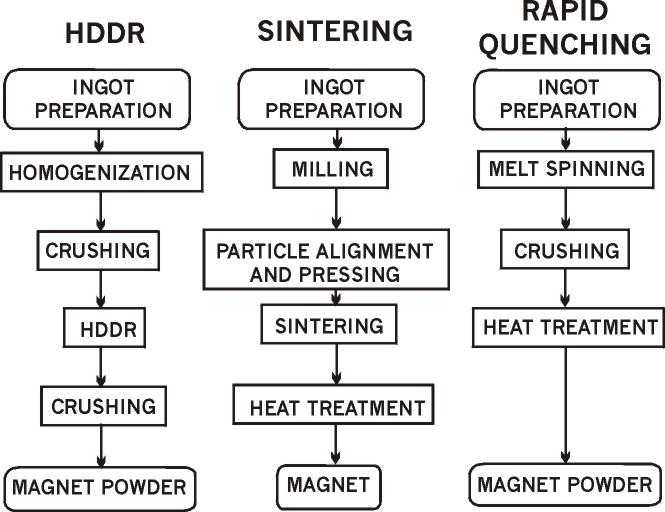

There have been several methods proposed to improve the magnetic properties

such as the powder metallurgy [2], rapid quenching [3], mechanical alloying [4],

hot working [5], sintering, etc. (see Fig. 1 [6]). However, these methods have

their limitations. For instance, the magnets produced by pulverizing the cast

ingot and then sintering did not show sufficient coercivities [7-8]. Moreover,

most of above-mentioned methods led to processing costincrease of permanent

magnets. For solution of this problem in last three decades have been proposed

some new approaches. For instance, in 1978 by Harris et al. [9] at first was

proposed method of hydrogen treatment of hardmagnetic alloys so-called

Figure 1.

The main methods permanent magnets production (after [6]).

Hydrogen Decrepitation (HD)

process.Hydrogen Decrepitation of Nd-Fe-B type magnets is a two stage process.

Firstly the hydrogen reacts with the Nd-rich phase at room temperature and then

at temperature increasing up ~ 160oC lead to second stage evolution

in which the hydrogen is absorbed by Nd2Fe14B matrix

phase. In both cases cracking occurs due to differential lattice expansion and

the resulting HD treated alloy is extremely friable. This allows milling times

to be reduced considerable and this is the main factor which reduces the overall

processing cost of permanent magnet manufacture. Thus, using of the HD process

led to increase of permanent magnets coercivity and also led to considerable

decreasing processing cost of permanent magnets on 16-25% [10].

The

recently developed in 1989 by Takeshita and Nakayama [11-12]

HDDR-process

(Hydrogenation- Decomposition-Desorption-Recombination) as a new method of

hydrogen treatment of hard magnetic alloys is very promising from this

viewpoint [13-15]. This HDDR-process provides a new strategy to improve the

properties of permanent magnets via hydrogen-induced phase transformations

in Nd2Fe14B powders. It was found that Nd2Fe14B

magnets produced by HDDR-treatment posses (BH)max more

8-10% than those by mechanical alloyed magnets [16]. Moreover, currently the

HDDR-process is the unique method for production of Nd-Fe-B type anisotropic

powders for permanent magnets (see Fig. 1) [17-19].

1. Principles of HDDR

process and HIDP-transformations

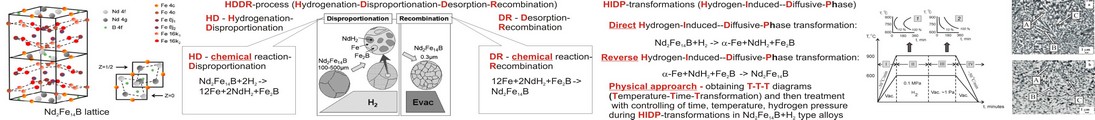

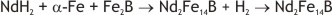

Earlier from the viewpoint of Chemistry the conventional HDDR process in Nd2Fe14B

hard magnetic alloys consists 4 of the following main stages: Hydrogenation,

Decomposition, Desorption, Recombination (see Fig. 2a). As a rule, on first

stage alloy absorbs hydrogen at room temperature (Hydrogenation) and then on

second stage at increasing of temperature up 750-900° C occurs process of

initial Nd2Fe14B alloy decomposition on NdH2,

and Fe2B phases (Decomposition). Subsequent hydrogen evacuation from

decomposed alloy (Desorption) leads to development of recombination process of

decomposed phases into initial Nd2Fe14B phase

(Recombination).

and Fe2B phases (Decomposition). Subsequent hydrogen evacuation from

decomposed alloy (Desorption) leads to development of recombination process of

decomposed phases into initial Nd2Fe14B phase

(Recombination).

The

main microstructural change during these HIDP-transformations is the conversion

from coarse grains into sub-micron grains (about 0.3-0.5

size, i.e.

comparable with the size of single magnetic domains [7-11]) whereby the magnetic

characteristics are expected to be significantly improved. This hydrogen-vacuum

treatment is perfectly suitable for producing powder samples with extremely high

coercivity, which can be used for producing the Nd-Fe-B base magnets by hot

high-pressure and bonding. size, i.e.

comparable with the size of single magnetic domains [7-11]) whereby the magnetic

characteristics are expected to be significantly improved. This hydrogen-vacuum

treatment is perfectly suitable for producing powder samples with extremely high

coercivity, which can be used for producing the Nd-Fe-B base magnets by hot

high-pressure and bonding.

On

the other hand, from the viewpoint of the Solid-State Physics and Material

Science, the HDDR process is based on the following

direct and

reverse

Hydrogen-Induced

Diffusive

Phase (HIDP)

transformations [20-21] (see Fig. 1b).

(1)

Direct HIDP-transformation:

in a hydrogen atmosphere (~ 0.1 MPa) at temperature range of 600-900, the

hydrogen-induced direct phase transformation (decomposition) occurs by the

following chemical reaction [21]:

(1)

(1)

(2)

Reverse HIDP-transformation:

the reverse phase transformation (recombination) occurs upon hydrogen evacuation

at ~ 10-2 Torr [21]:

(2)

(2)

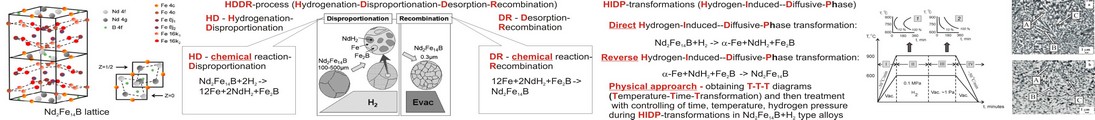

Moreover, the treatment scheme in the case of HIDP-transformations (see Fig. 2b)

which at first was proposed by Rybalka et. al. [21] is principally different

from conventional HDDR treatment scheme (see Fig. 2a). In this case, the Nd2Fe14B

alloy is heated up in vacuum to high temperatures first (stage I on Fig. 2b),

and then at this constant temperature the reaction chamber is filled with

hydrogen to develop the direct HIDP-transformation (stage

II

on Fig. 2b). Afterwards, when the direct HIDP-transformation is done the

hydrogen is evacuated from chamber, which leads to the development of reverse

HIDP-transformation (stage

III

on Fig. 2b). Finally, when reverse HIDP-transformation development is

finished the Nd2Fe14B alloy powder cooled down to room

temperature in vacuum (stage IV on Fig. 2b).

Figure 2. a)

Scheme of conventional HDDR-process (after Takeshita [6]); b) Scheme of

hydrogen treatment based on HIPD-transformations (after Rybalka et al. [21]).

2. Kinetics of the

HIDP-transformation in Nd2Fe14B

type alloys and permanent

magnets properties

It has been established that the magnetic properties

of permanent magnets strongly depend on their microstuctural features [1]. For

instance, the coercive force of permanent magnets is a function of

microstuctural features, such as the average grain size of hard magnetic phase,

grain size distribution, degree of magnetic isolation of hard magnetic phase

etc. [1]. However, the microstuctural features depend on the processing

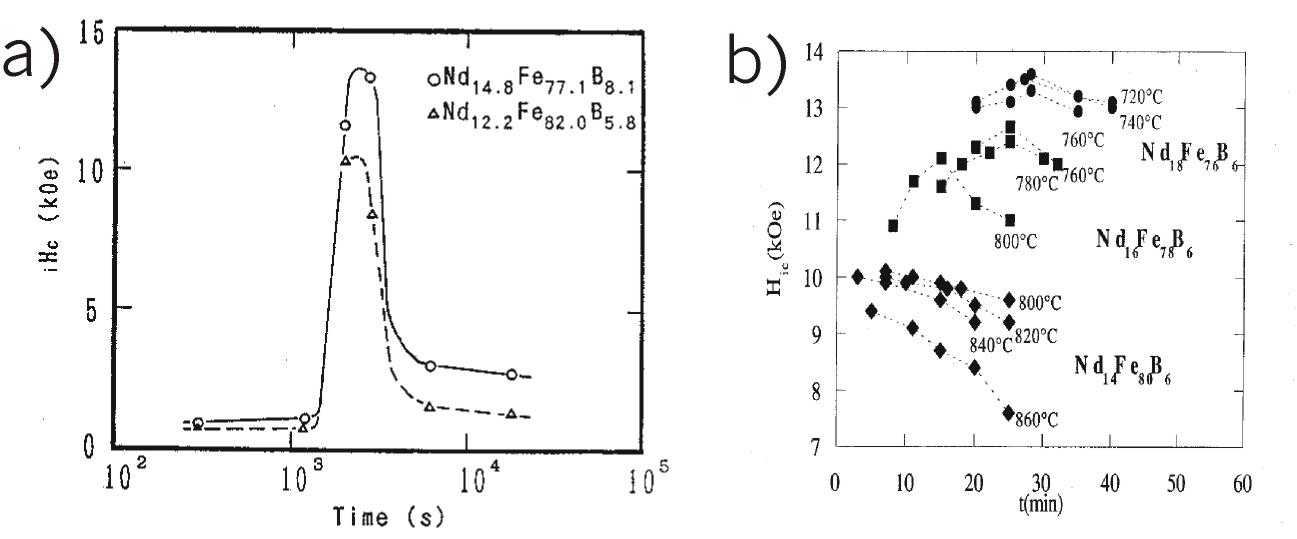

conditions. For instance, as shown in Fig. 3, the permanent magnets’ coercivity

is a function of such important kinetic parameters as the transformation time

and temperature during the reverse HIDP-transformation in Nd2Fe14B

type alloy [6,22]. This phenomenon of coercivity decrease might be resulting

from the abnormal grains growth processes in case if hydrogen-vacuum treatment

has been carried out after full finishing of HIDP-transformation in Nd2Fe14B

type alloy. If the hydrogen-vacuum treatment in Nd2Fe14B

type alloy carry out without taking into account the kinetic features, such as

the hydrogen pressure, temperature and transformation time according to

conventional HDDR scheme treatment (see Fig. 2a) it can lead to the abnormal

grains growth of hard magnetic phase (Ф

on Fig. 2a) up to tens-hundreds

[23].

[23].

Thus, this

kinetic factor

is one of the main factors that lead to coercivity decrease in Nd2Fe14B

type permanent magnets.

Back

to Top

In contrast to the conventional HDDR scheme treatment, if hydrogen-vacuum

treatment is carried out in accordance with the HIDP-transformation scheme based

on T-T-T (Temperature-Transformation-Time) isothermal kinetic diagrams in Nd2Fe14B

type alloy (II

and III

on Fig. 2b) it leads to homogeneous microstructure of Nd2Fe14B

alloy with sub-micron grains of Nd2Fe14B hard magnetic

phase (Ф

on Fig. 2b) and high degree of its magnetic isolation [24,25]. This fact is

prerequisite for improving permanent magnets coercivity [1] made from powder

treated by this way.

Figure 3.

Permanent magnets coercivity dependence on temperature and transformation time

exposure during reverse HIDP-transformation in Nd2Fe14B

type alloy: a) Takeshita's data [6], b) Liesert's data [22].

So far, researches on the hydrogen-induced phase transformations in Nd2Fe14B

type alloy earlier was limited in the following aspects:

(1) After the classical work by Davenport and

Bain on ferrous alloys [26], it has been well accepted that the isothermal

kinetic diagrams are the primary bases for heat treatment of steels, alloys and

compounds. For the hydrogen-induced phase transformations in Nd2Fe14B

type alloy, however, there is little data on these critical process parameters.

Most of the published hydrogen-vacuum experiments conducted to date have been

carried out empirically without taking into account the kinetic features, such

as the hydrogen pressure, temperature and transformation time and it led to

abnormal growth grains processes and coercivity decrease of permanent magnets.

However, our group has been demonstrated the possibilities of constructing of

the T-T-T isothermal kinetic diagrams hydrogen-induced phase transformations

(HIDP-transformations) in Nd2Fe14B type alloy and also was

shown that kinetics of these type transformations is strongly depend from

temperature treatment and hydrogen pressure [21,27-31]. Moreover, preliminary

experiments based on the T-T-T kinetic diagrams lead to microstructure

homogenization of Nd2Fe14B alloy [32] and submicron grains

of Nd2Fe14B hard magnetic phase (0.3-0.8  )

with high degree of its magnetic isolation [24,25]. )

with high degree of its magnetic isolation [24,25].

(2) There has been very little correlation

between microstructural changes and processing conditions for the

HIDP-transformations.

(3) As a rule, most of the experiments were

carried out on laboratory samples without any real world applications.

3. Conclusions

Thus, we believe that in future a systematic investigation of the

HIDP-transformation

kinetics

and microstructure features

in Nd2Fe14B industrial alloy based on treatment scheme

according Fig. 2b may lead to a

new improved technology of treatment

of Nd2Fe14B hard magnetic alloys, which in future may be

extended on many others classes of hard magnetic materials.

REFERENCES

-

P. Campbell,

Permanent magnet materials and their application, Cambridge University

Press, 1994.

-

M. Sagawa, S.

Fujimura, N. Togawa et al., J. Appl. Phys., 1984, 55, 2083.

-

J.J. Croat, J.F.

Herbst, R.W. Lee et al., J. Appl. Phys., 1984, 55, 2078.

-

L. Schultz, J.

Wecker, E. Hellstern, J. Appl. Phys., 1987, 61, 3583.

-

R.W. Lee,

Appl. Phys. Lett., 1985, 46, 790.

-

T. Takeshita,

J. Alloys Comp., 1995, 231, 51.

-

H.H. Stademaier,

N.C. Lui, Matter. Lett., 1986, 4, 304.

-

C.R. Paik, H.

Mino, M. Okada, H. Homma, IEEE Trans. Mag. Magn., 1987, MAG-23, 2512.

-

Harris I.R.,

McGuiness P.J. Proc. XI Int. Workshop on Rare-Earth Magnets and Their

Applications, Pittsburg, 1990, 29.

-

O.M. Ragg, G.

Keegan et. al., Int. J. Hydrogen Energy, 1997, 22, 333.

-

Takeshita T.,

Nakayama R. Proc. X Int. Workshop on Rare-Earth Magnets and Their

Applications, Kyoto, 1989, 551.

-

Takeshita T.,

Nakayama R. Proc. XI Int. Workshop on Rare-Earth Magnets and Their

Applications, Pittsburg, 1990, 49.

-

X.J. Zhang, P.J.

McGuiness, I.R. Harris, J. Appl. Phys., 1990, 69, 5838.

-

T. Takeshita,

J. Alloys Comp., 1993, 193, 231.

-

O. Gutfleisch,

I.R. Harris, Proc. XV Int. Workshop on Rare-Earth Magnets and Their

Applications, Dresden, 1998, 487.

-

V.N. Verbetsky,

Doctoral thesis, Moscow State University, Moscow, 1998.

-

R. Nakayama, T.

Takeshita, M. Itakura et al., J. Appl. Phys., 1994, 76, 412.

-

T. Takeshita, K.

Morimoto, J. Appl. Phys., 1996, 79, 5040.

-

T. Takeshita, R.

Nakayama, IEEE Trans. J. Magn. Jap., 1993, 8, 692.

-

V.A. Goltsov,

J. Alloys Comp., 1999, 293-295, 844.

-

Rybalka S. B.,

Goltsov V. A., Didus V. A. and Fruchart D. J. Alloys Comp., 2003,

356-357, 386.

-

Liesert S. These

docteur de physique, CNRS, Grenoble, 1998.

-

E. Estevez, J.

Fidler, C. Short, I.R. Harris, J. Phys. D: Appl. Phys, 1996, 29, 951.

-

Rybalka S. B.,

unpublished data.

-

Krayushkina E.Yu., Rybalka

S.B.,

Yurasova V.Yu. Formation of ultrafine nanocrystalline microstructure during

hydrogen-induced reversible phase transformations in Nd2Fe14B

type magnetic alloy // IHISM'15 Junior: Proc.

X International School for young scientists named after A.A. Kyrdumov

'Interaction of Hydrogen isotopes with structural Materials', Sarov, Russia.

— 2016. — P. 108-118.

-

Davenport E.S.,

Bain E.S. AIME Technical Publications , 1930, 90 (348), 117.

-

V.A. Goltsov,

S.B. Rybalka, V.A. Didus, D. Fruchart, Progress in hydrogen treatment of

materials, ed. by V.A. Goltsov, Coral Gables, 2001, 367.

-

Didus V. A.

Rybalka S. B., Fruchart D. and Goltsov V. A. J. Alloys Comp., 2003,

356-357, 390.

-

V.A. Goltsov,

S.B. Rybalka, A.F. Volkov, Int. J. Hydrogen Energy, 1999, 24, 913.

-

V.A. Goltsov,

S.B. Rybalka, A.F. Volkov et al., Metal Physics and Advanced Technologies,

1999, 21, 22.

-

V.A. Goltsov,

S.B. Rybalka, A.F Volkov et al., The Physics of Metals and Metallography,

2000, 89, 363.

-

A.A. Didus,

S.B.Rybalka, V.A. Didus, A.F.Volkov,

Bull. DonGASA,

2001, 3, 15.

Back

to Top

Back

to Main page

|